我们是经验丰富的制造商

超过75年的定制设计和螺纹加工制造经验保证了我们的质量。 我们在自己的工厂中进行完整的加工制造过程,包括热处理和特殊涂层。

Material used in the manufacture of flat, cylindrical and planetary thread rolling dies for both mechanically and dimensionally demanding applications. The profile of thread rolling tools manufactured from D2 wears down progressively. This causes the bottom of the thread to go from having a radius to becoming a flat zone, even if the geometric dimensions of the threaded part are correct. As a result of this effect, the size of the radius of the bottom of the threaded part increases and, in turn, the roughness in this area of the profile grows significantly, diminishing the quality of the threaded part.

The end result is an excessive inconsistency between the parts threaded at the beginning and the end of the thread rolling tool's service life and a very high level of roughness on the radii of the bottom of the threaded parts. The tools that HEROSLAM manufactures using M2 material maintain a great consistency with regard to the dimensions and quality of the final product throughout the majority of the thread rolling tool's life cycle. The effects of wear and tear become apparent only in the final stretch of the thread rolling tool's life cycle and not during the majority of its service life, as may occur in the case of a tool manufactured using D2 material.

In this aspect, what distinguishes HEROSLAM from its competitors is the GOGOR (GG) treatment, which markedly increases the thread rolling tool's service life (see TREATMENTS). The application of this GG coating developed in-house by HEROSLAM allows our customers to carry out fewer machine preps and changes, minimizing machine down time. All of this entails a significant reduction in manufacturing costs, which translates into lower cost per piece. HEROSLAM recommends using M2 to thread stainless steel parts and treated pieces, as long as they do not exceed a hardness of 36HRC.

我们认为高质量的钢材是生产高质量螺纹模具的基础,因此我们只与欧洲最顶尖的钢铁公司合作。

为每种螺纹选择合适的材料,对于制造最佳性能的螺纹模具具至关重要。 因此,我们根据客户的具体需求和具体应用,使用不同类型的钢材制造我们的模具。

作为研发领域的先驱,我们与钢材供应商开展密切深入的合作,为提高模具性能而专门开发特殊合金和新材料。

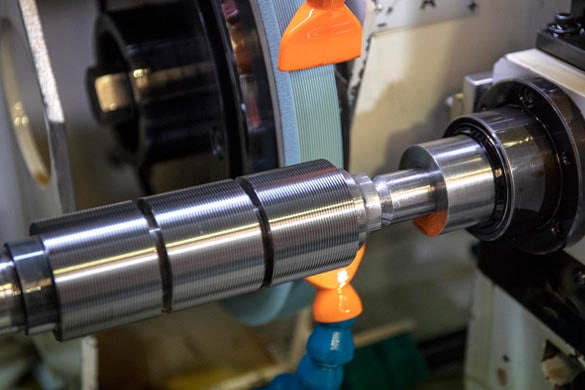

我们是磨削制造模具的专家

通过磨削制造的螺纹滚压模具比其他制造工艺(例如机加工或铣削)生产的模具具有更高的精度和耐用性。 因此,我们Heroslam是磨削技术的专家,我们的模具可以满足高标准的外形质量与精密度,确保模具的优越性能。

我们在自己的工厂中进行完整的模具加工制造过程,包括热处理和我们工具的特殊涂层。

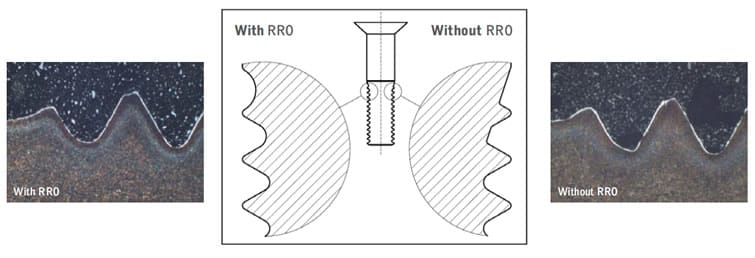

由于我们对于滚压工艺有着丰富的经验,我们设计了自己的特殊螺纹外形和RRO收尾。得益于我们先进的磨削技术以及现代化的数控设备,我们可以生产特定外形与特殊收尾的模具,以满足客户的特殊需求,提高螺纹的质量以及我们模具的性能。