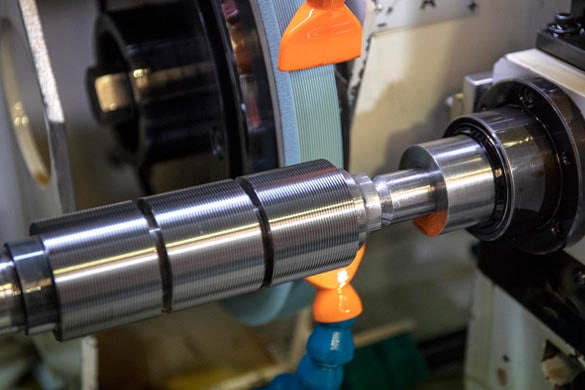

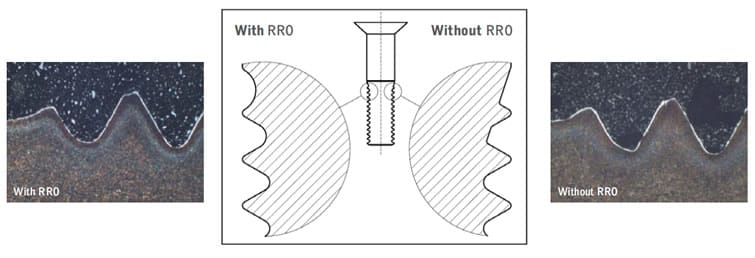

Material used in the manufacture of flat, cylindrical and planetary thread rolling dies for both mechanically and dimensionally demanding applications. The profile of thread rolling tools manufactured from D2 wears down progressively. This causes the bottom of the thread to go from having a radius to becoming a flat zone, even if the geometric dimensions of the threaded part are correct. As a result of this effect, the size of the radius of the bottom of the threaded part increases and, in turn, the roughness in this area of the profile grows significantly, diminishing the quality of the threaded part.

The end result is an excessive inconsistency between the parts threaded at the beginning and the end of the thread rolling tool's service life and a very high level of roughness on the radii of the bottom of the threaded parts. The tools that HEROSLAM manufactures using M2 material maintain a great consistency with regard to the dimensions and quality of the final product throughout the majority of the thread rolling tool's life cycle. The effects of wear and tear become apparent only in the final stretch of the thread rolling tool's life cycle and not during the majority of its service life, as may occur in the case of a tool manufactured using D2 material.

In this aspect, what distinguishes HEROSLAM from its competitors is the GOGOR (GG) treatment, which markedly increases the thread rolling tool's service life (see TREATMENTS). The application of this GG coating developed in-house by HEROSLAM allows our customers to carry out fewer machine preps and changes, minimizing machine down time. All of this entails a significant reduction in manufacturing costs, which translates into lower cost per piece. HEROSLAM recommends using M2 to thread stainless steel parts and treated pieces, as long as they do not exceed a hardness of 36HRC.